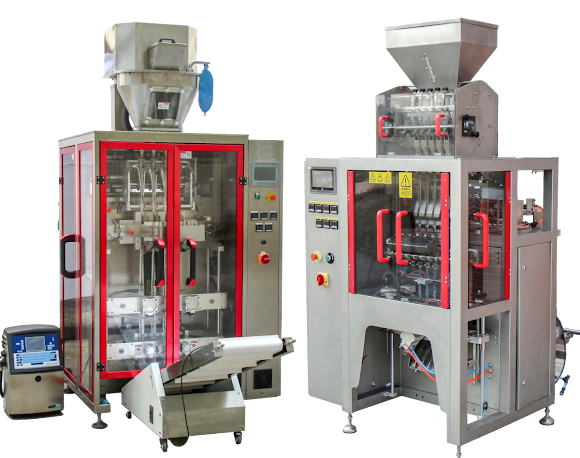

High-grade packaging equipment represents the pinnacle of innovation and efficiency in the packaging industry. These state-of-the-art machines are designed to meet the stringent demands of modern production environments while delivering exceptional performance and reliability. Here are some key features and benefits of high-grade packaging equipment:

High-grade packaging

equipment for incorporates cutting-edge technology to automate and

optimize the packaging process. This includes features such as servo-driven

systems, PLC control, touch-screen interfaces, and real-time monitoring

capabilities, enabling precise control and seamless operation.

These machines

and packaging equipment for are required in different industries like food,

pharmaceuticals, cosmetics, or consumer goods, these machines can handle

diverse packaging needs with ease.

Efficiency and Productivity

With their

advanced features and automation capabilities, high-grade packaging equipment

can significantly improve efficiency and productivity in manufacturing

operations. They can perform tasks such as filling, sealing, labeling, and

palletizing with speed and accuracy, reducing downtime and increasing

throughput.

Quality Assurance through Advanced Machines and

Equipment Range

High-grade

packaging equipment for is designed to deliver consistent and high-quality

packaging results, ensuring product integrity and safety. These machines are

equipped with features such as automatic fault detection, quality control

systems, and precise dosing mechanisms to minimize errors and defects.

Cost Savings Option to Ease the Packaging Process

While high-grade

packaging equipment for may require a significant initial investment, it offers

long-term cost savings through improved efficiency, reduced labor costs, and

decreased product waste. By optimizing the packaging process, these machines

help companies achieve higher levels of profitability and competitiveness in

the market.

0 Comments